A warehouse racking system is the workhorse of storage in most warehouses. Imagine a collection of sturdy, industrial shelves built to safely and efficiently stack your inventory. But it’s much more than just shelves! Here’s the lowdown:

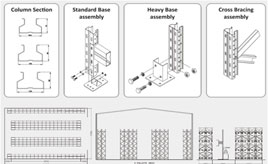

Structure:

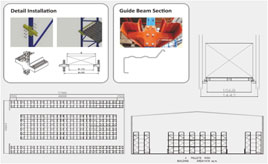

- Frames: These are the sturdy backbone of the system, made of strong upright and horizontal beams that create the basic framework. Think of them as the building blocks.

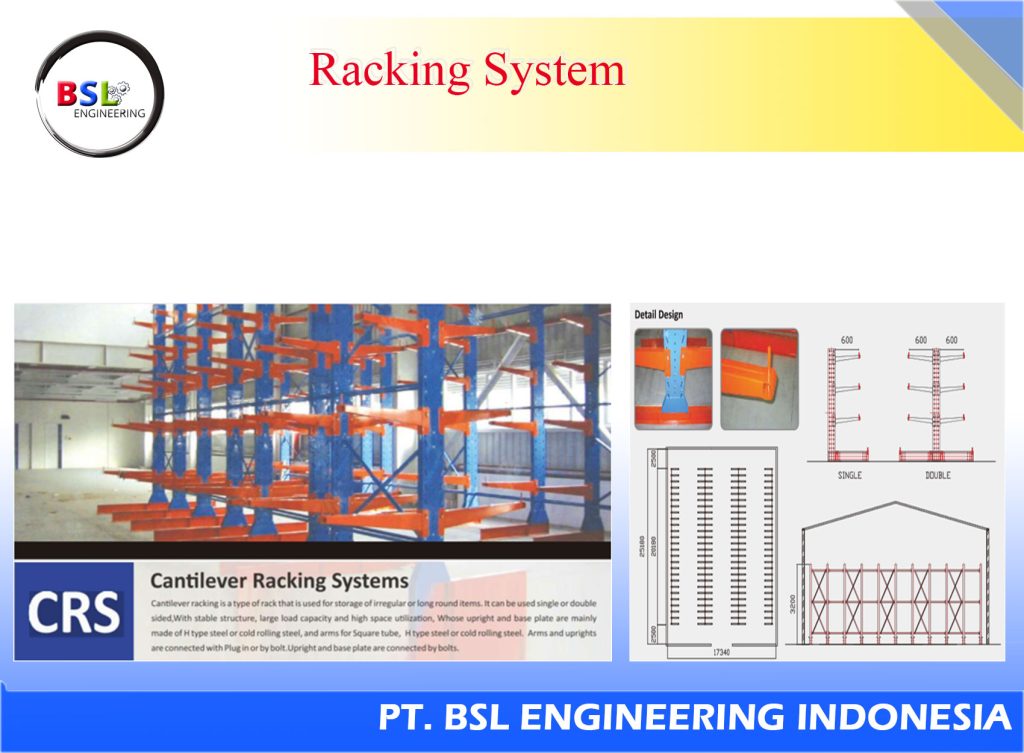

- Beams: These rest on the uprights and directly support the weight of your goods. They come in various materials like steel and timber, depending on the weight they need to handle.

- Decking (optional): These are platforms placed on the beams, creating a solid surface for storing smaller items or loose boxes directly on the rack.

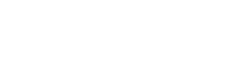

Types of Racking Systems:

- Selective Pallet Racking: The most common type, offering direct access to each pallet and ideal for diverse inventory sizes and turnover rates. Think of it as a neatly organized library for your palletized goods.

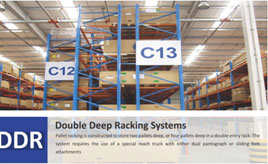

- Double Deep Racking: This space-saving champion stores pallets two deep, but accessing the inner ones requires removing the front one. Think of it as a compact filing cabinet for pallets, efficient but not ideal for frequently accessed items.

- Drive-In Racking: Imagine a network of tunnels where forklifts drive directly in to store and retrieve pallets. This high-density system is perfect for warehouses with lots of similar items, but accessing specific pallets can be trickier.

- Gravity Flow Racking: This one uses gravity to move pallets from loading to unloading, ensuring a “First-In-First-Out” (FIFO) flow for your inventory. Think of it as a gently sloping slide for your pallets, maximizing space and keeping things organized.

Benefits of Racking Systems:

- More Storage, Less Space: Maximize your vertical space, squeezing in more inventory without expanding your warehouse footprint.

- Inventory Control Simplified: Organized placement and easy access make picking and restocking a breeze. No more rummaging through piles!

- Safety First: Keeping items off the floor and securely supported reduces the risk of product damage and injuries.

- Efficiency Boost: Forklifts travel shorter distances, and finding items becomes quicker, streamlining your warehouse operations.

Choosing the Right Racking System:

The best system for you depends on your specific needs. Think about:

- Inventory Type and Weight: Big, heavy boxes? Small, light parts? Choose a system that can handle your specific types of goods.

- Warehouse Layout and Space: Make sure the system fits your available space and allows for smooth forklift movement.

- Budget and Accessibility: Different systems have varying costs and access considerations.

Remember, consulting with a warehouse storage specialist can help you choose the perfect racking system to optimize your operations and unlock your storage potential.

PT.BSL ENGINEERING INDONESIA

Specialist in Material Handling, Engineering, Design and Procurement PT.BSL Engineering Indonesia

021-2927650 0812-9811-1780 (Telp./WA)

Ruko Sentra Niaga Kalimalang, Jl. Ahmad Yani, Kayuringin Jaya, Bekasi, Jawa Barat 17000